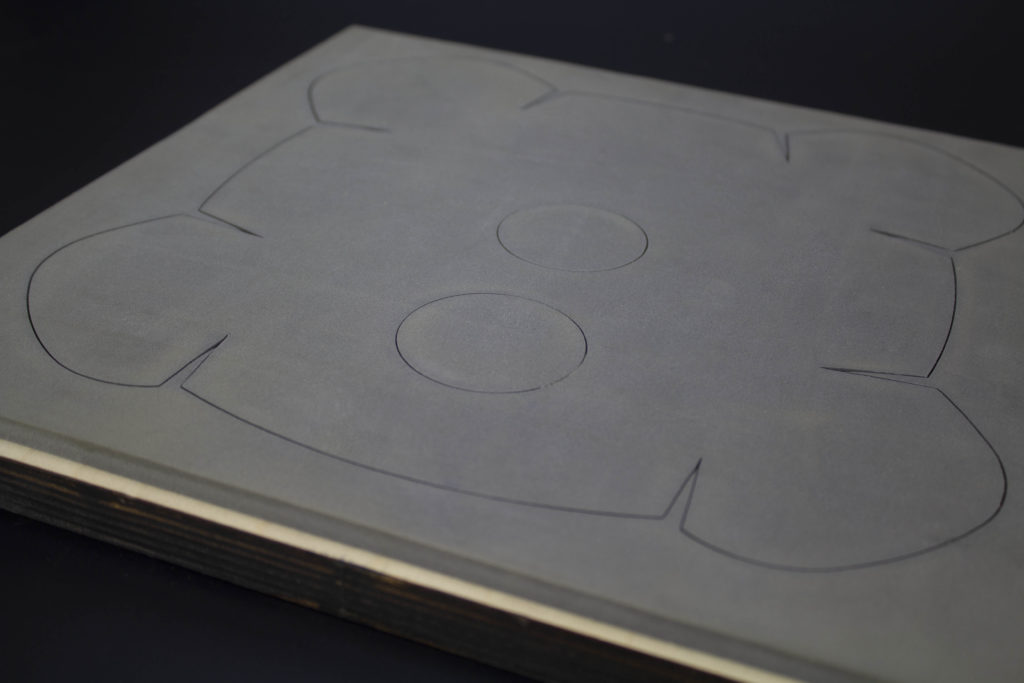

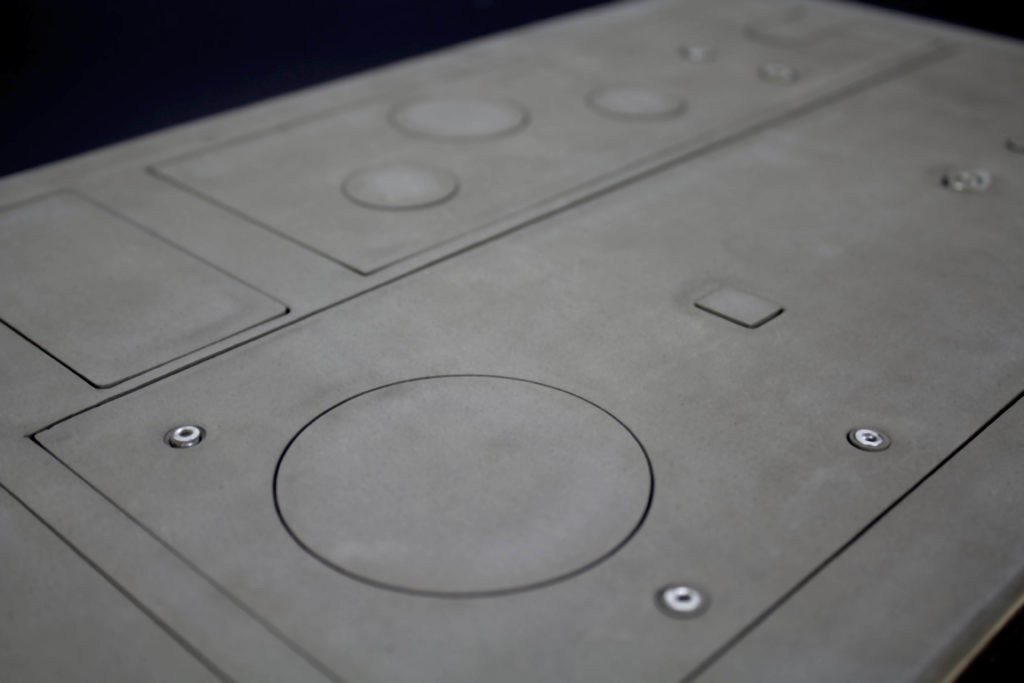

Die Cutting

Processes

The combination of speed and bespoke ruled tooling enable our machines to power through large finishing runs quickly and efficiently. From old school traditional platens to automated flat beds with camera assisted registration.

Technical Spec

Process Features

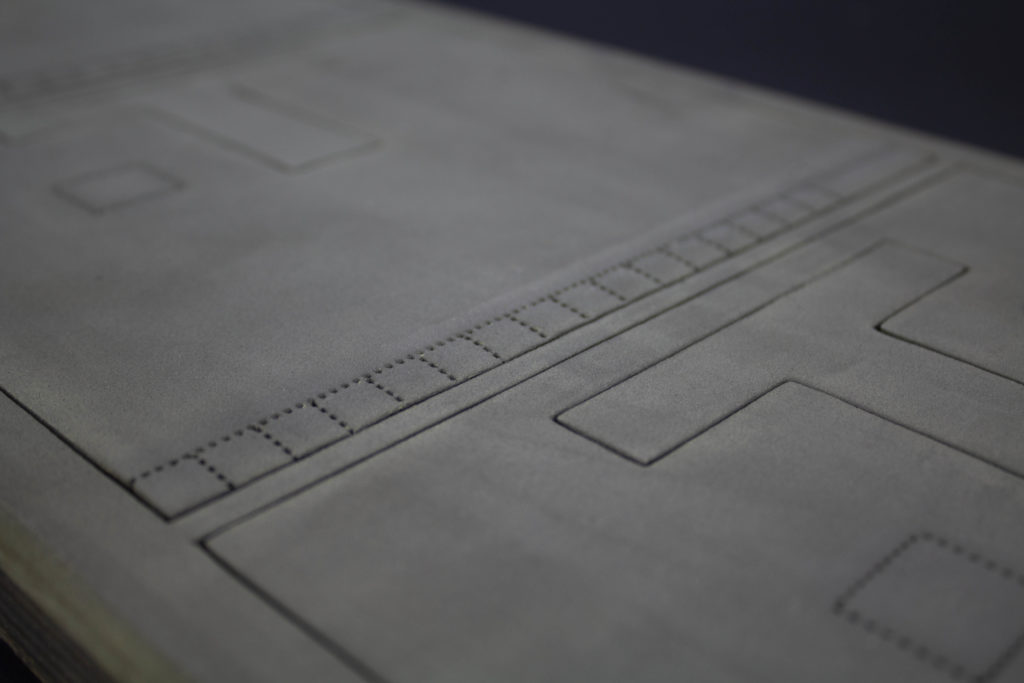

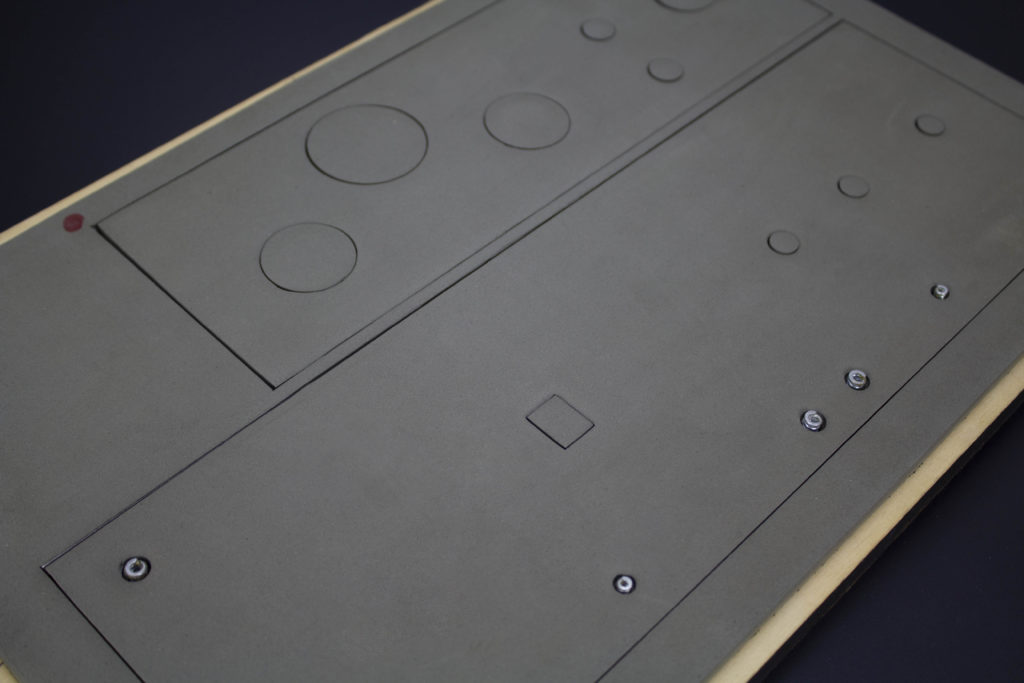

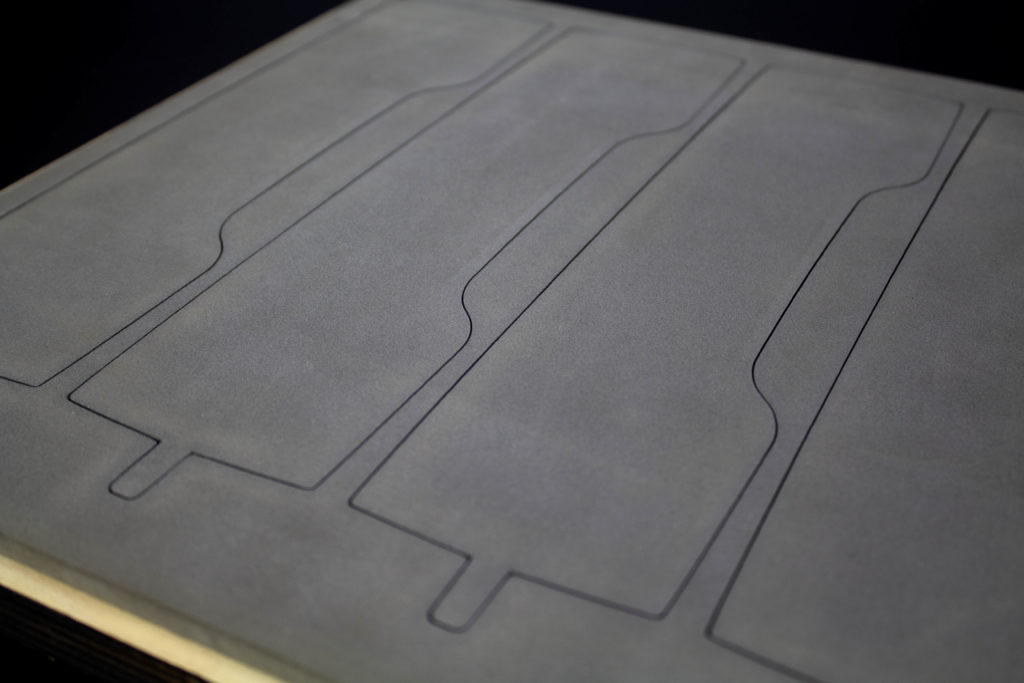

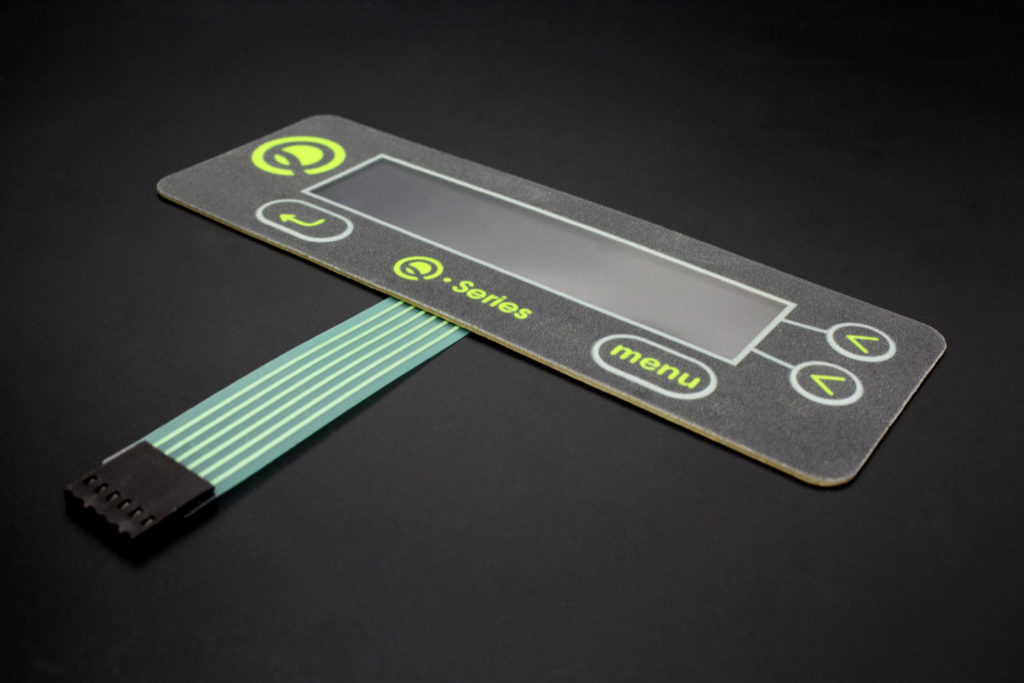

- Blade cut - cutting all the way through

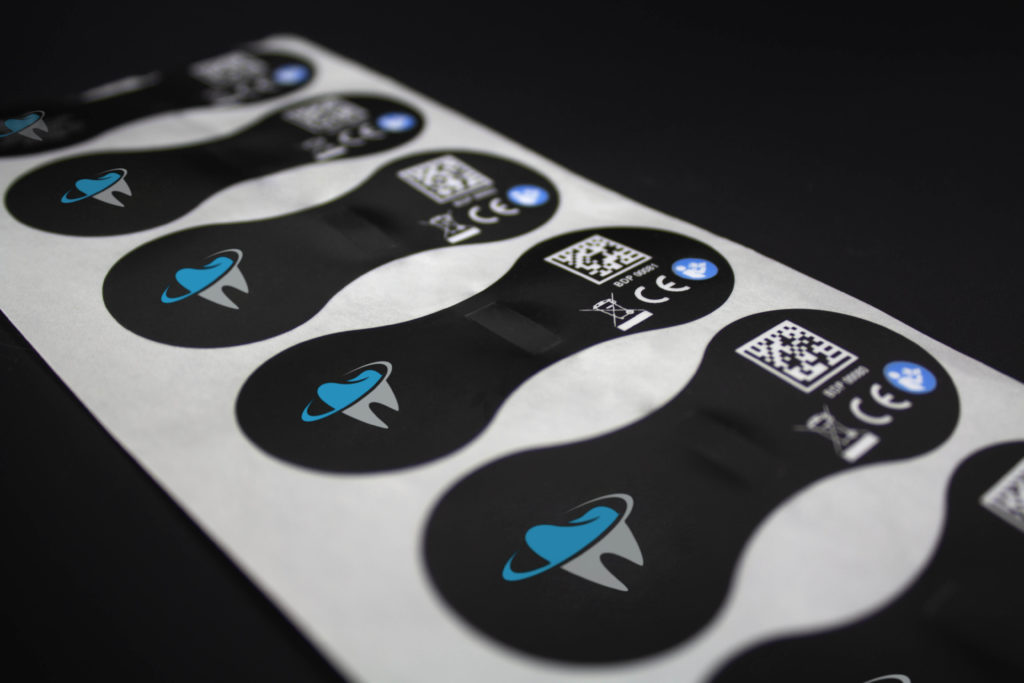

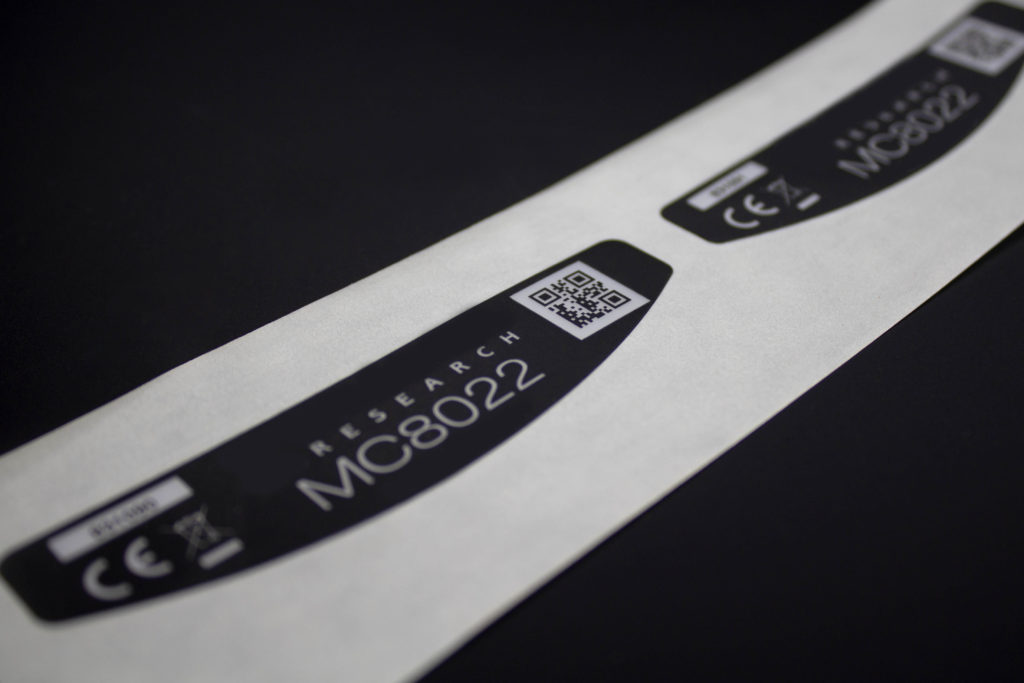

- Kiss cut - just cutting the top layer leaving the release liner untouched

- Small detail and holes achievable

- Consistent tolerance levels

- Camera recognition

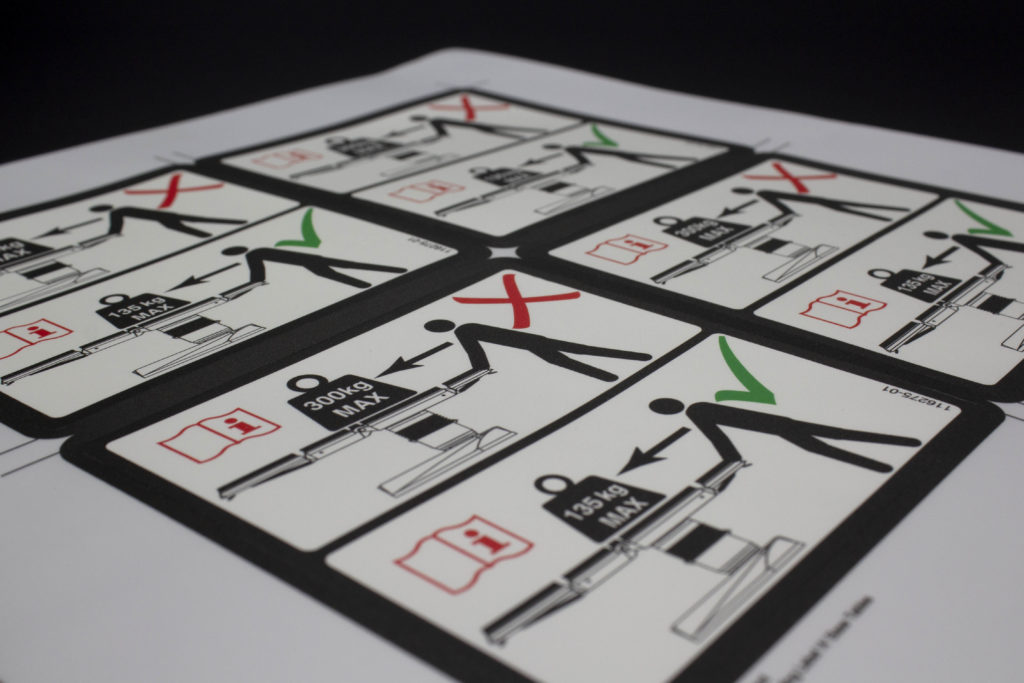

Typical Applications

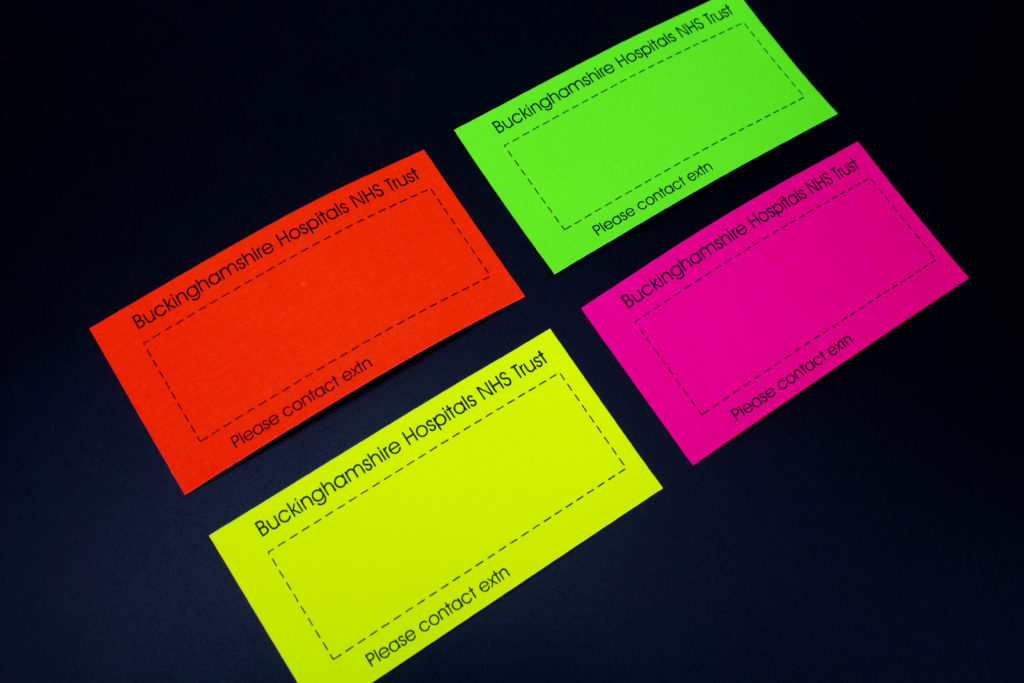

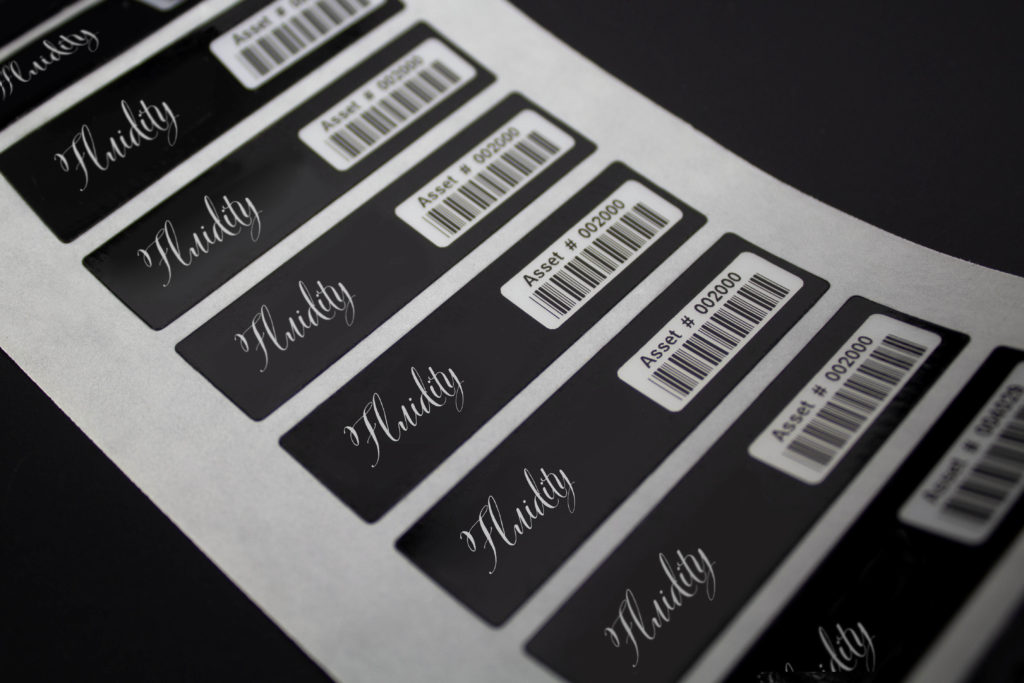

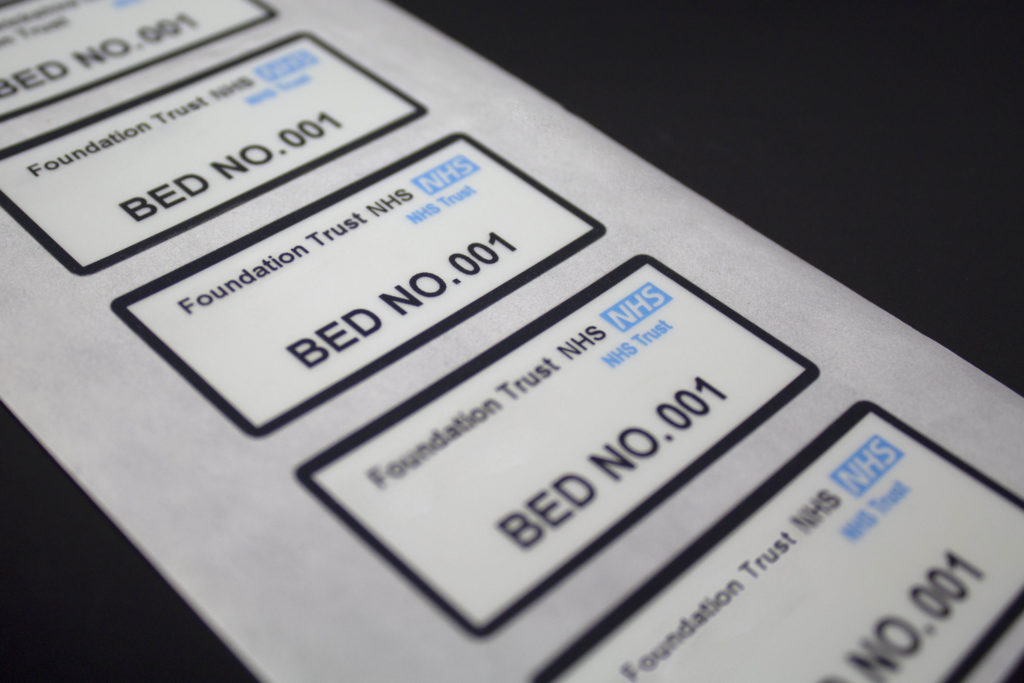

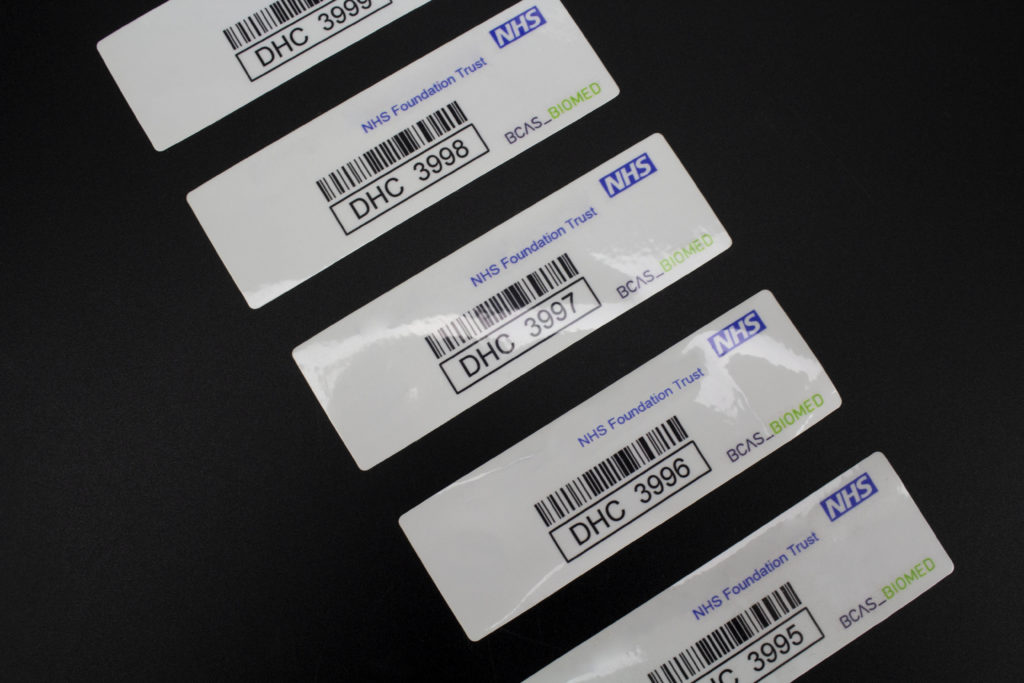

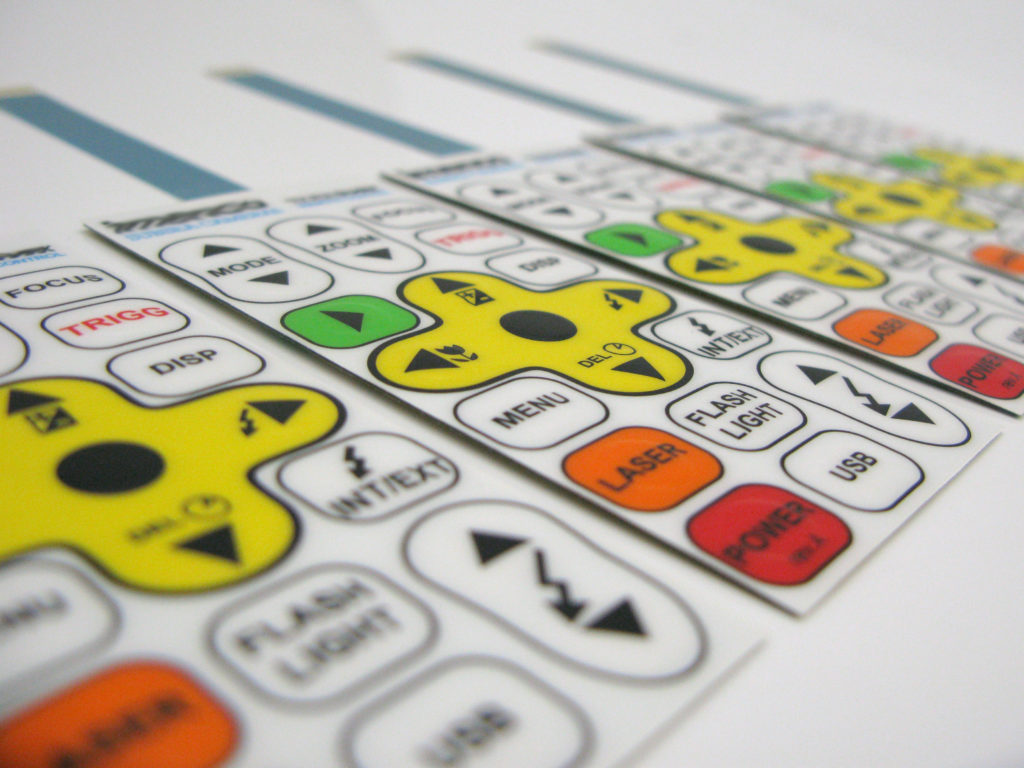

- Self Adhesive Labels

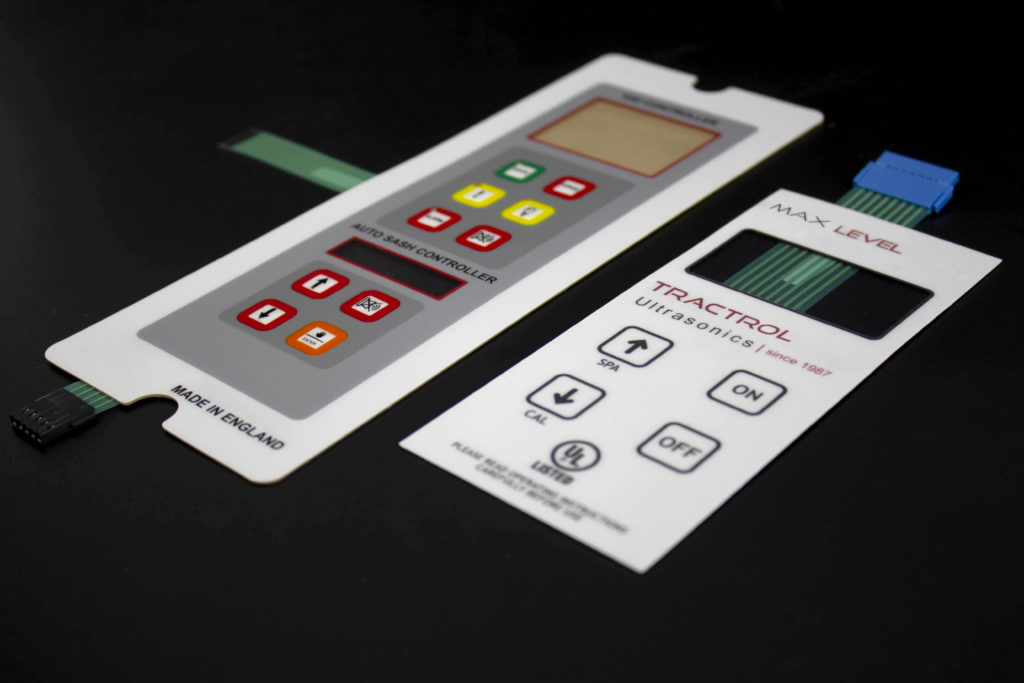

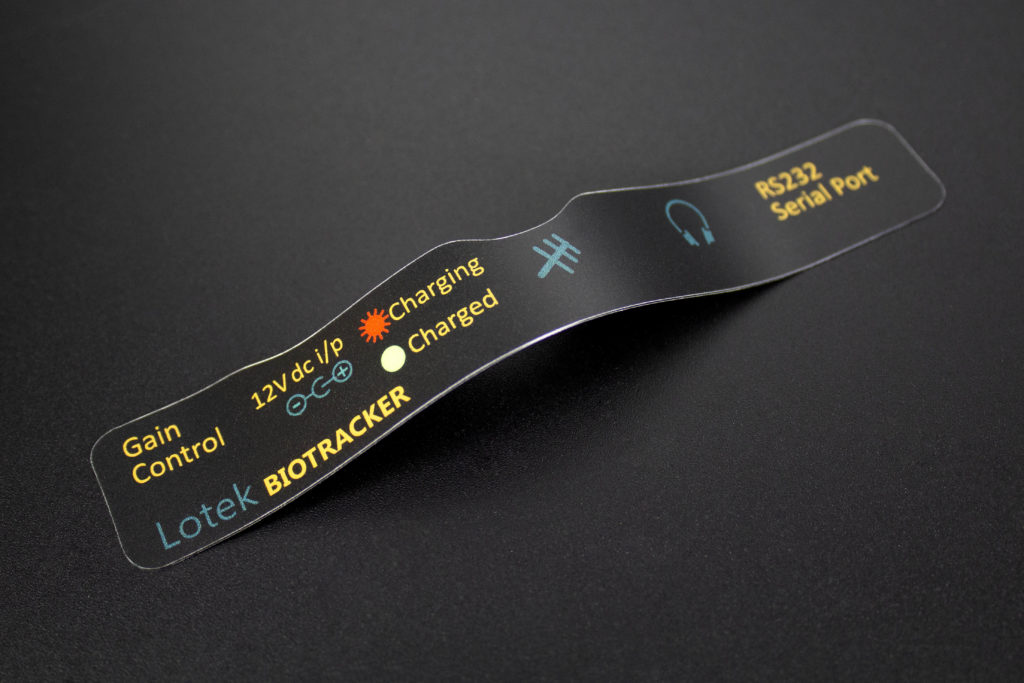

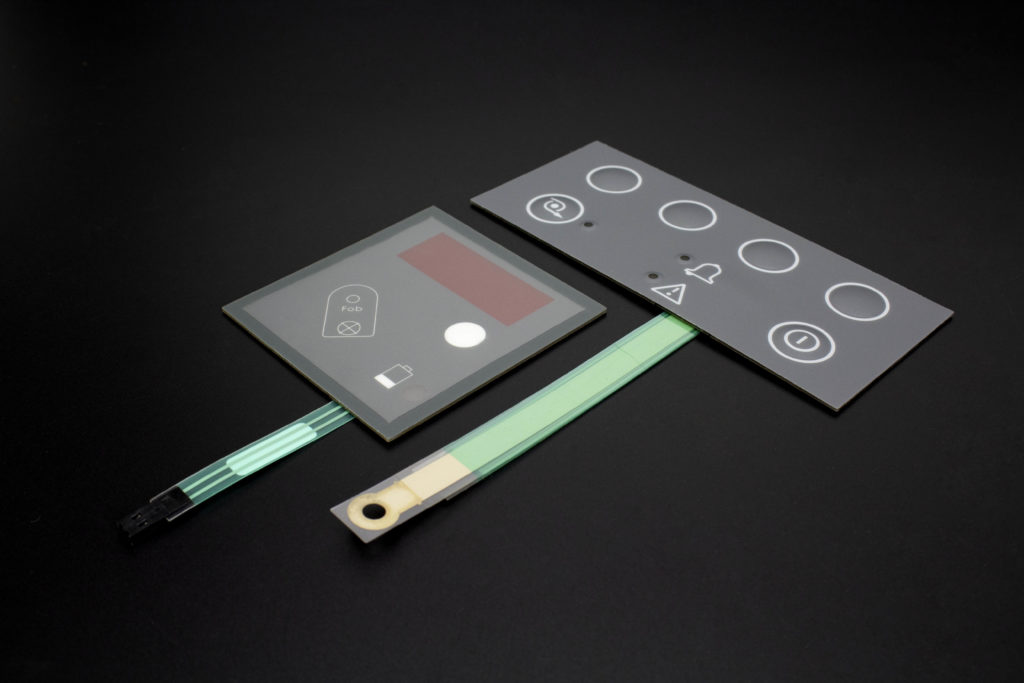

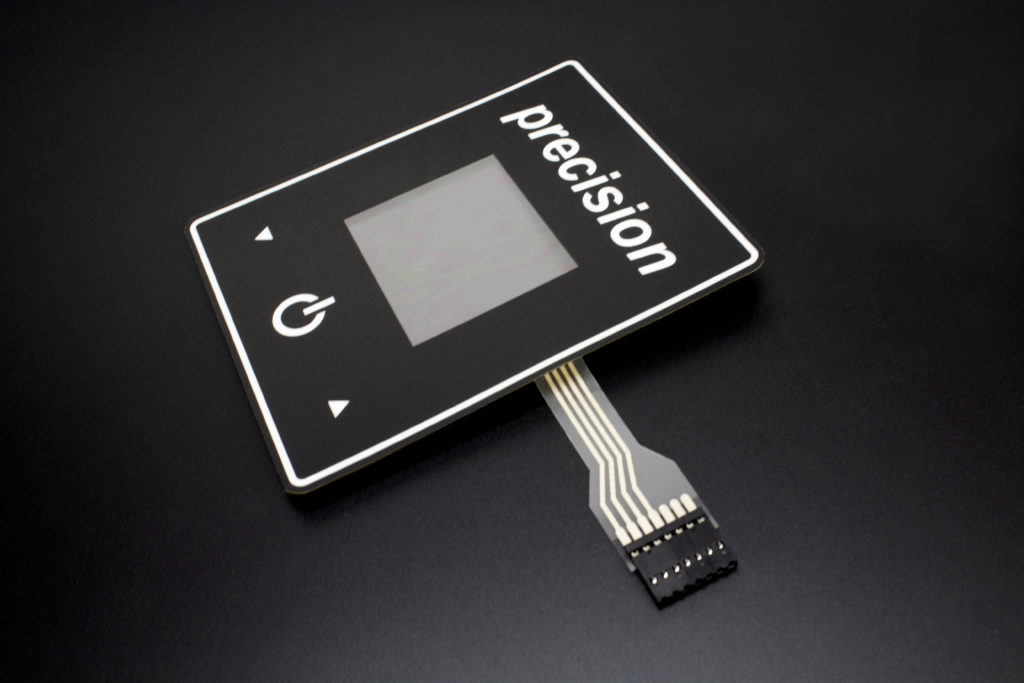

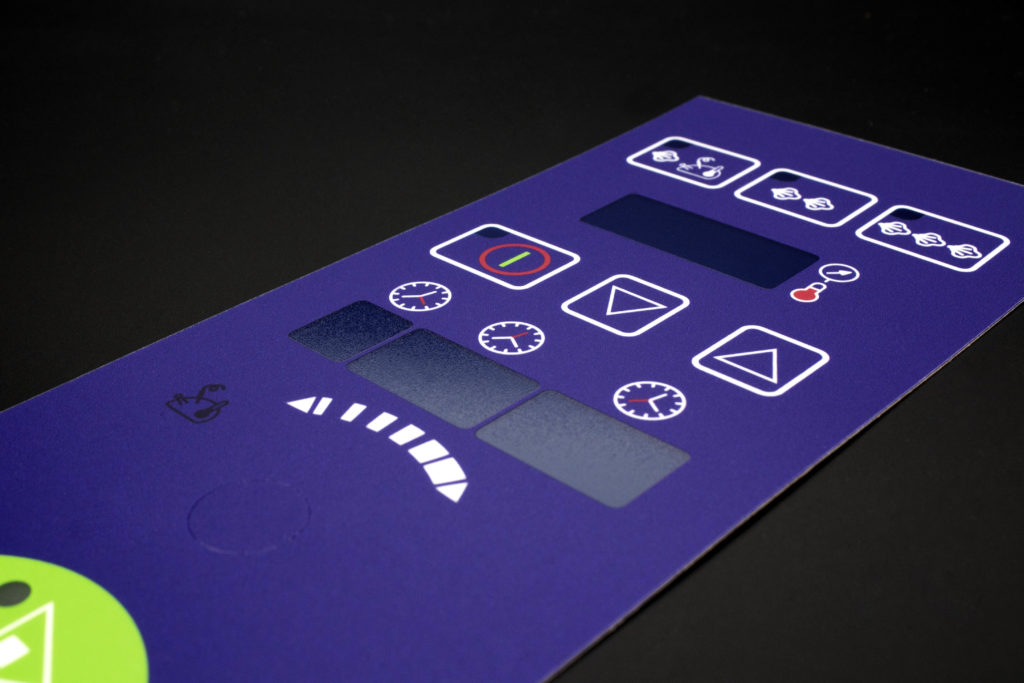

- Graphic Overlays

- Membrane Keypads – combined with emboss

- ID cards

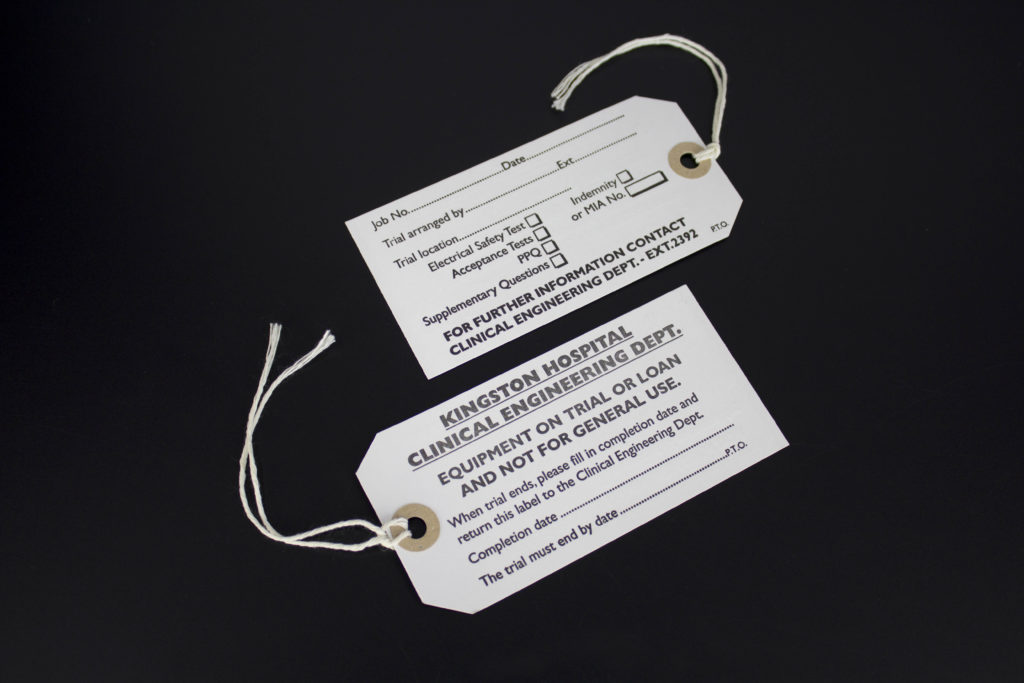

- Tags

Material Options

Name:

MRPVC

Finish:

Clear | Gloss | Textured

Thickness:

upto 400 micron

Name:

Polyester

Finish:

Clear | White | Gloss | Matt

Thickness:

upto 200 micron

Name:

Vinyl

Finish:

Clear | White | Coloured | Gloss | Matt

Thickness:

upto 100 micron

Name:

Aluminium

Finish:

Anodised | Milled | Brushed

Thickness:

1mm

Name:

Card

Finish:

White | Smooth

Thickness:

upto 400gsm

Name:

Foam

Finish:

Black | White

Thickness:

1mm

Name:

Rubber

Finish:

Neorprene

Thickness:

1mm

Maximum Size

600mm x 450mm

View Our Work

Latest Insights

Browse our curated section of news and useful articles.

Let's discuss your project.

Whether you have a full brief or just an idea, we'd love to share our expertise with you.

Contact us“I would like to take the opportunity to thank you for all the effort in achieving what turned out to be a first class product, when you consider all the...”

“Really pleased with the work and the super quick turn around. Many thanks”

“Thank you so much Colin. We’re so happy to have these new editions to our bindery.”

“I just wanted to say thank you for the help recently given to us by your Company. The effort put in by all of your team to get over the problem and ensure we...”