What products can be customised?

Almost all products can be customised either by printing, laser marking or engraving. Limitations on size and shape may factor and not all materials can be marked using all these processes. It’s best to discuss the concepts early with professionals like us in order to find the right choice.

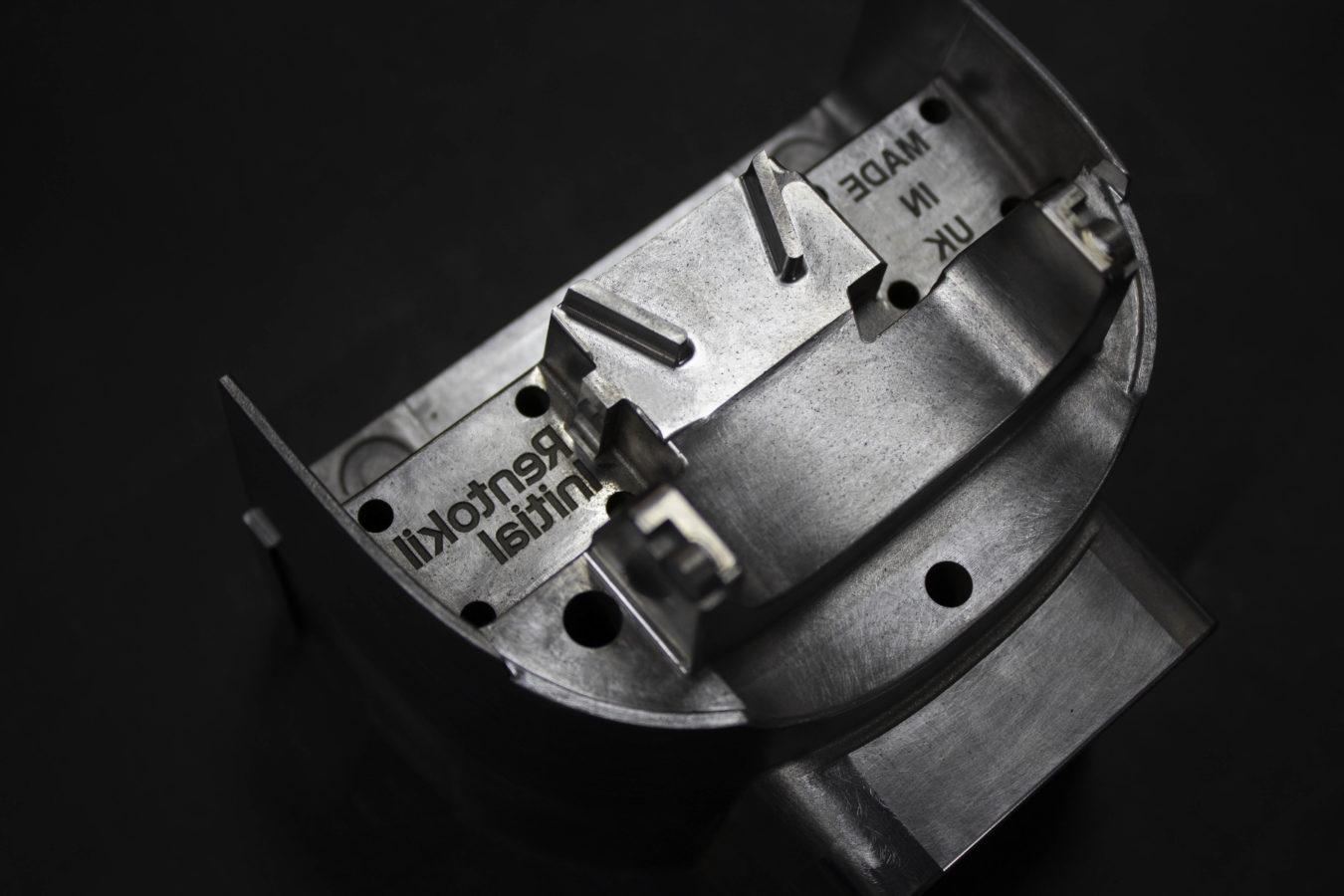

Whilst all three methods have their specific use, laser marking is the most common choice. It’s speed, permanency and versatility, combined with precision detail and the ability to mark both flat and 3D components make it a firm favourite.

A free issue part can be anything from a tube, disc or plate to electronic housing and casings, calibration equipment, machine front panels and parts. Stainless steel and aluminium parts laser with ease, leaving a smooth to the touch finish, hardly altering the surface of the material texturally, but creating a high contrast effect with the guarantee that the mark is completely permanent.

Fine Cut are happy to discuss your requirements, but please note we do have a minimum order charge of £60 +artwork.

Services we offer

- Branding – We can take your finished products and apply your logo. Large or small batches welcome.

- Personalisation – Applying names to a product to give it that unique and personal touch.

- Serialisation – Available in human-readable and coded forms such as Barcodes, QR codes or Data Matrix.

- Certification and insignias – applying decals

- Final packaging and shipping – After the final touches are made, we can help facilitate the packaging and shipping to your end customers. White label services available.