Our Journey to Solar Powered Energy

News

In the wake of a worldwide energy crisis, and costs soaring, we bit the bullet and invested into solar power in a bid to reduce our energy bills, but also step towards a greener future and reducing our carbon footprint.

Energy price increases have affected every bill payer in the World following the Covid-19 Pandemic and the invasion of Ukraine, resulting in increased prices of oil, gas and electricity. As everyone struggles with the increases, businesses face astronomical energy bills.

At Fine Cut, our electricity costs doubled in just one year. And in a business environment, reducing energy costs is difficult, when machines need to run, lights need to be on continually, and therefore cutting back on output is not always a feasible option.

Our Journey to Going Green –

We looked at internal strategies we could put in place to reduce our energy output, our first step was to insulate the entire factory wherever possible. We identified in the areas where we have suspended ceilings the air temperature was not maintained, so we started insulating all these ceilings and the results have been dramatic, these areas now maintain a workable temperature and we saw an instant reduction in gas and electricity usage.

We sought business support from LoCASE – dedicated to helping South and East SMEs with grant funding which we were able to utilise for the insulation of the factory and office.

Next up, we had the entire premises roof re-clad ahead of our solar project, this was a slightly lengthy process but crucial that we knew the roof was in good order before the solar panel install.

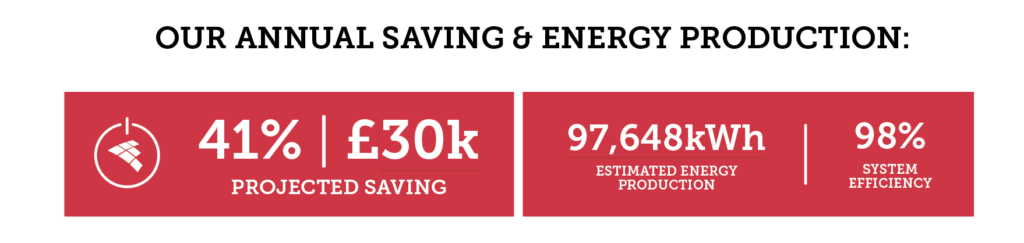

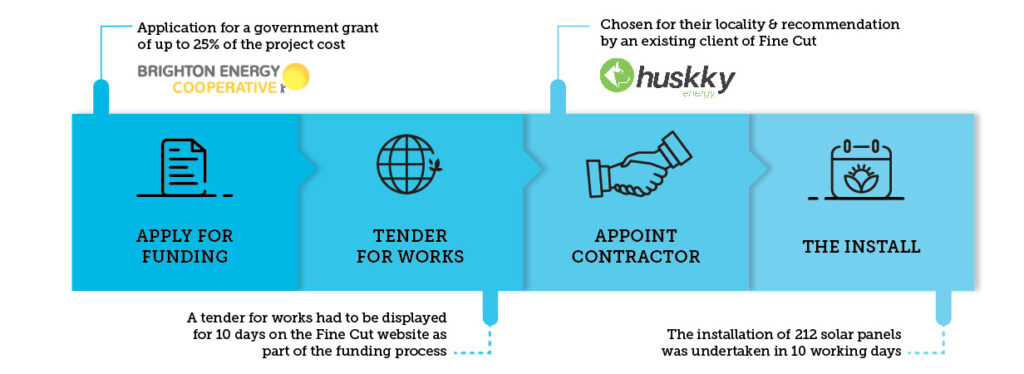

We put forward our application to Brighton Energy for a grant to install solar panels, at the time, the grant available would cover up to 25% of the cost – capped at £25k. So even with this grant, it was a large outlay, but with a forecast that the solar panel array should generate 40-50% of our energy required annually, it was a worthy investment going forward.

We had to go through the tender process, vetting three potential contractors for the project. We appointed Huskky Energy, who were not only local to us, but had been highly recommended by a client as well. Huskky Energy are a family run business, dedicated to supplying ethically sourced products, installed by fully qualified professionals and offered a quick turnaround and professional approach.

It took just 10 days to install 212 solar panels to the roof of Fine Cut. Each panel generates energy on a daily basis, and annually will be collectively generating around 100,000kW hours. The installation promised to generate signifiant environmental benefits and put us on the road to going green and reducing our carbon footprint.

Environmental Analysis:

- 1775 Trees will be saved per year

- 29,489L of equivalent fuel not required per year

- 33,515kg of coal not being burnt a year

- 34.33kg CO2 equivalent reduction per annum

So how does it work?

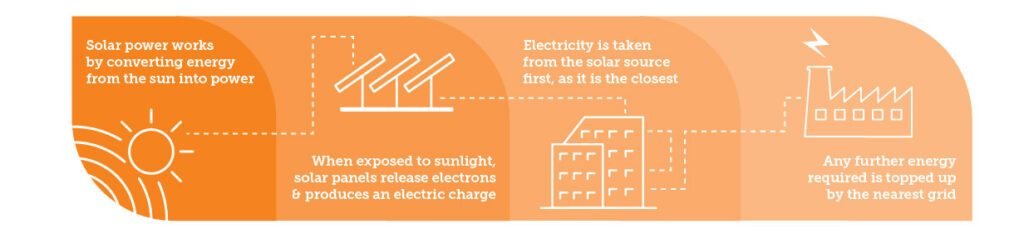

Solar power works by converting energy from the sun into power. There are two forms of energy generated from the sun for our use – electricity and heat. Solar panels are usually made from silicon, or another semiconductor material, installed in a metal panel frame with a glass casing. When this material is exposed to photons of sunlight (very small packets of energy) it releases electrons and produces an electric charge, known as a photovoltaic charge.

This photovoltaic charge creates an electric current, specifically, direct current which is captured by the wiring in solar panels. This direct current electricity is then converted to alternating current by an inverter. Alternating current is the type of electrical current used when you plug appliances into normal wall sockets.

Electricity is lazy, so it will always take the easy route from the source to the output. Therefore it will take from the solar panelled roof source first as its closest and then will top up from the grid if / when required.

Monitoring the Efficiency of our Solar Project –

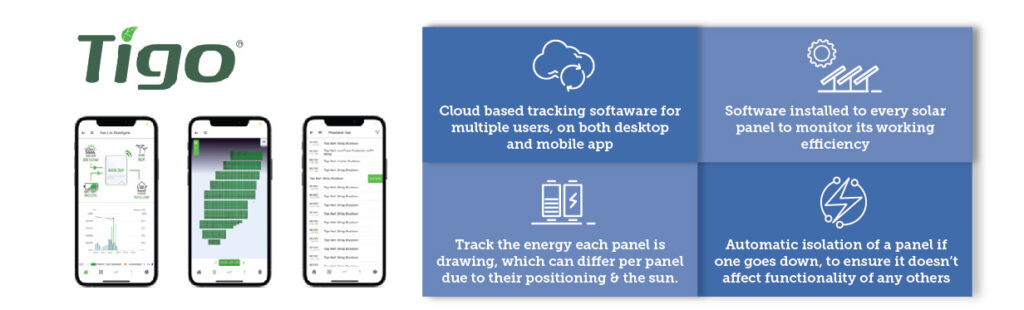

TIGO is the monitoring software provided with the install and available for multiple users on desktop and mobile app. It is connected to every solar panel and monitors whether they are working efficiently, tracking how much energy each panel is drawing – (some panels produce more energy than others due to their positioning and that of the sun). And if one panel were to go down, it will be automatically isolated, to ensure it doesn’t affect any others.

Let's discuss your project.

Whether you have a full brief or just an idea, we'd love to share our expertise with you.

Contact us“Just wanted to say a big thanks for the laser cuttings of the cardboard. The guys were really pleased with them, and thought the cost was very reasonable too,...”

“I just wanted to thank you and your company very much for all the time and effort you put into this project. I know it was very last minute and you really...”

“Just a quick note to say a big ‘thankyou’ for turning this order of the labels around so quickly. This has really helped us out with keeping...”

“The overlays have just arrived – and they’re outstanding, you’ve got a VERY happy customer : ) Please send my personal thanks to the team for getting...”