What is Laser Marking & How Does it Work?

Articles

A surprisingly simple, yet effective, durable and cost efficient process for marking a wide range of materials – from metals to woods, plastics and free issue customer supplied parts. Here we explain what Laser Marking is and how it works.

What Is Laser Marking?

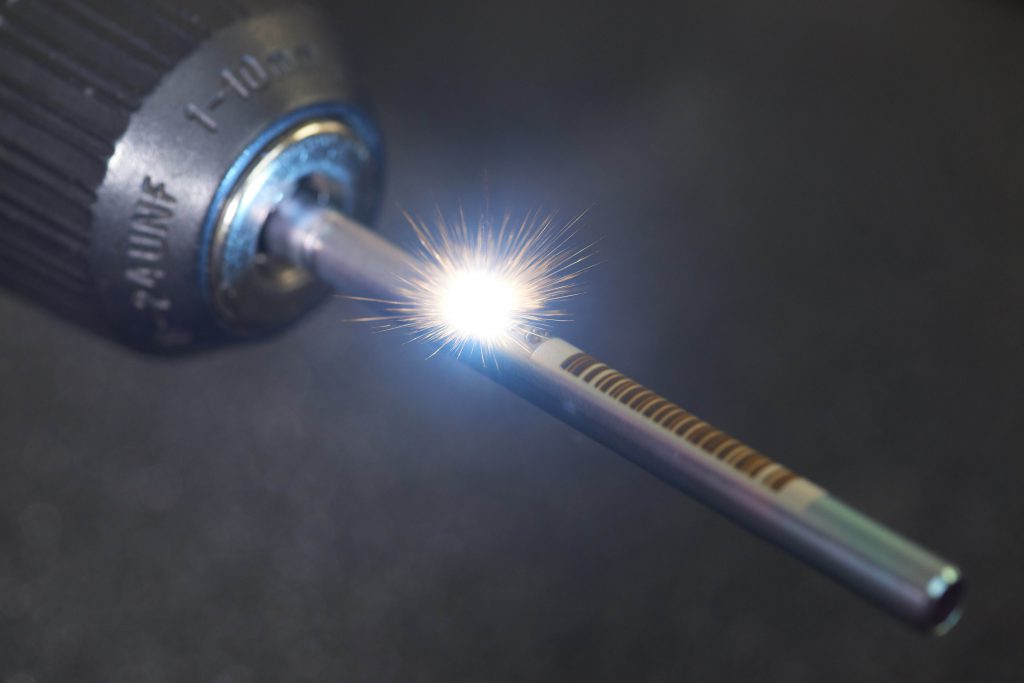

Laser Marking is a process which uses a constant beam of concentrated light to create a mark on a surface. When the laser beam hits a surface, the energy produced is transferred in the form of heat – the focused beam of light alters the materials properties and appearance creating precise, high contrast marks on to almost any surface.

The energy released by a laser beam is measured in ‘wavelengths’ (or nanometres) – the higher the wavelength, the more powerful the beam. The different levels of wavelengths are attributed to different types of laser machines which are suited to different applications;

Fibre Lasers – This wavelength is perfect for marking metals because the high energy is absorbed by the material

CO2 Lasers – Able to generate wavelengths to cover a wide range of organic materials such as wood, but also plastics such as Acrylic

We house both types of laser machine at Fine Cut and therefore can fulfil almost any requirement.

Read Full Spec on Laser Marking

The Different Types Of Laser Marking

‘Laser Marking’ is an overarching term used to describe several different types of mark the process can achieve:

1. Laser Marking

A surface mark, with no depth, used mainly for marking metals by carbonising the surface and altering the properties and/or appearance with low power to cause colouration without altering the surface texture. Also known as annealing (see below) carbon migration, coloration and foaming.

2. Laser Engraving

This process is when the laser physically removes some of the surface material to create a mark with depth. The high heat during the process causes the material to essentially vaporise. The depth is determined by the amount of times the material is hit with the laser. Can be used for metal or plastic, but laser engraving of metal is slow and therefore not as cost effective as machine engraving, however more detail is achievable with laser engraving.

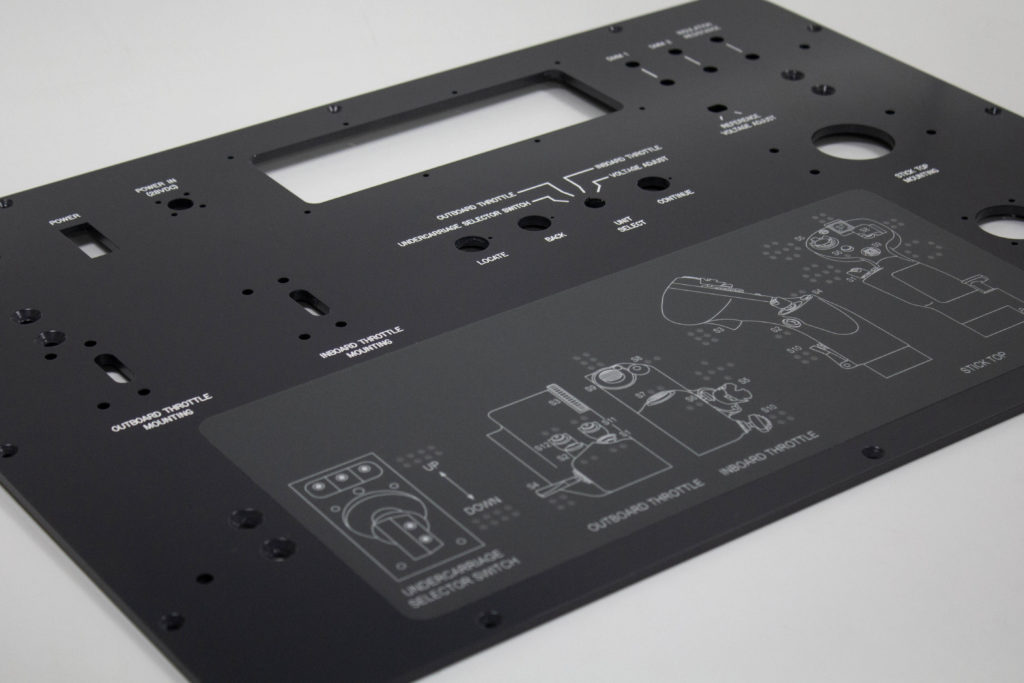

3. Laser Etching

So called by its resemblance to chemical etching , but with no depth. Using a high heat the laser causes the surface of the material to melt – it expands and creates a raised mark. Used to create high contrast, dark marks at speed. Laser etching is mainly used on anodised aluminium to remove the surface colouration to reveal the natural metal underneath as a contrast colour. Also suitable for complex diagrams or designs & pictures from a jpg image.

4. Laser Annealing

This is when the mark is generated under the surface – by slowly heating the metal, it begins to oxidise under the surface and by tightly controlling the parameters, different colours can be achieved.

5. Laser Ablation

Similar to laser Etching, it refers to the removal of a particular surface coating to reveal the metal underneath , examples are Day / Night switches for car instruments , whereby the painted surface is commonly referred to as laser ablated.

The Advantages of Laser Marking;

It’s actually greener than you think

Laser machines are very environmentally friendly, unlike print, which requires consumables such as inks, plastics and chemicals, lasers require nothing more than their power source. Fibre lasers run off electricity and CO2 lasers run off CO2 funnily enough! The machines require very little maintenance and have no real consumables.

Permanent yet forgiving

Although a laser mark is a permanent mark and with the heat and power behind it can seem quite abrasive, unless you go for an engraving which has depth to it – the surface is virtually unaltered in texture when laser marking metals. Particularly popular when it comes to the marking of free issue parts and for tolerance sensitive parts.

Long lasting precision

The high contrast marks are permanent and durable, and will stay forever legible as well as being chemically and thermally resistant. Precision provides consistent results for multiple parts, ensuring a nearly perfect readability rate and a low rejection rate.

Super-fast technology

Quick turnaround times and tight deadlines can be achieved with laser marking, as it still proves to be the fastest direct to object marking process. With no pre or post production processes required either, laser marking is a very popular method for the marking, branding and personalising of both industrial and promotional products.

Let's discuss your project.

Whether you have a full brief or just an idea, we'd love to share our expertise with you.

Contact us“I just wanted to say thank you very much for sorting out the plaques for us for the Shoreham aircrash, they both looked fantastic, my client is very pleased!”

“Part arrived this morning, now they are ready for dispatch to our customer, can’t thank you enough for the quick turnaround, it’s very much...”

“We received these nice and early Friday – thank you – and they are lovely! Just what we wanted. Thanks for a very quick turnaround!!”

“Thanks for excellent job you did on the copper panels. The end result was fantastic.”