The Kawasaki ZX10R Project

Case Studies

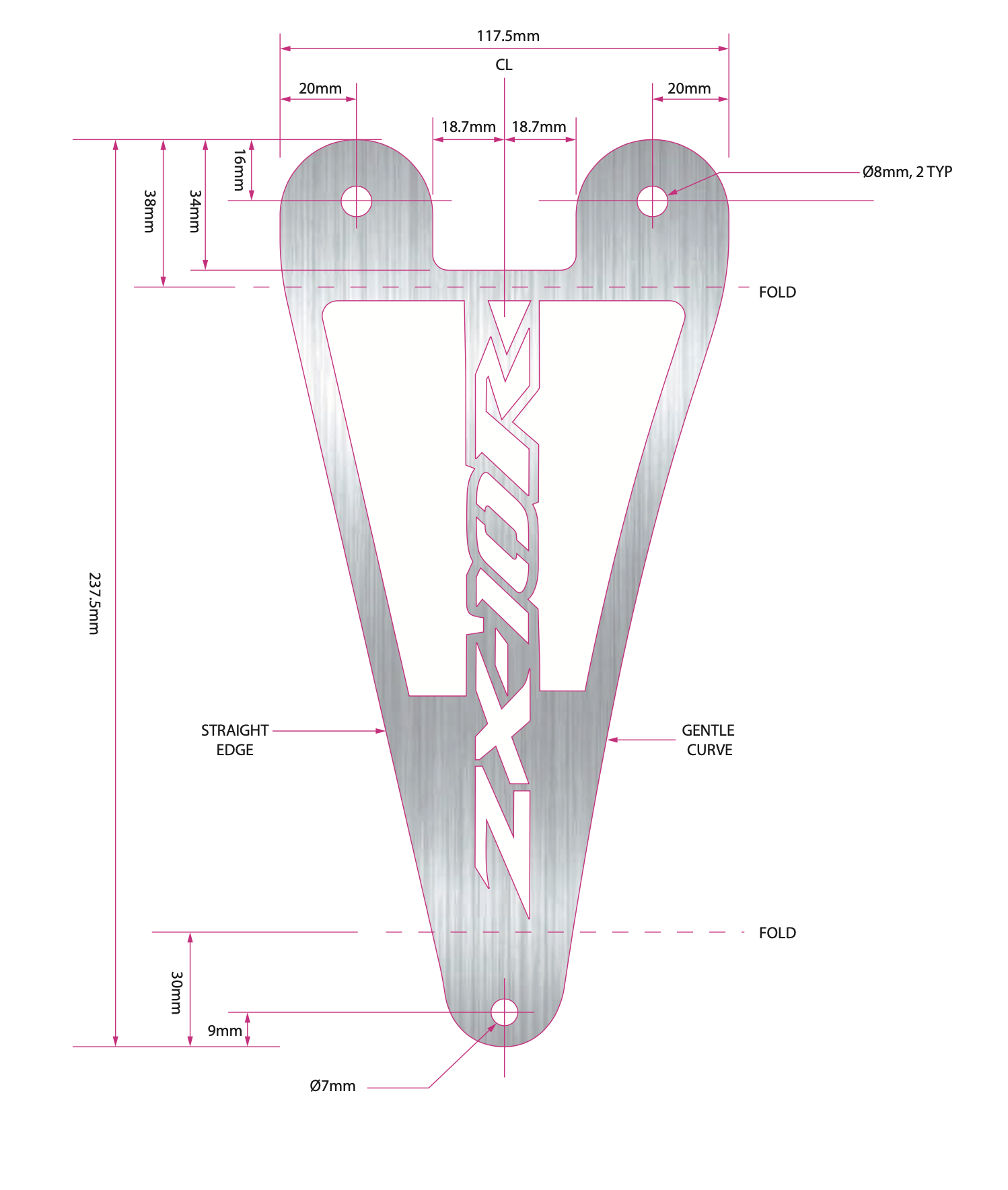

We were approached by the bike owner who wanted to create a completely custom exhaust hanger for his Kawasaki Ninja.

The client supplied an existing hanger which was correct in size, shape and fit for the bike, our team had to first un-bend and straighten out the part for creating a useable template. The part was then scanned into our design software and the profile was redrawn by one of our design team to the exact measurements, including where the bends and fixing holes would be.

A bespoke graphic for the ZX10R design needed to be created by our designer to fit the shape of the hanger – they had to ensure that the design was tabbed so that all of the design stayed within the metal when it was cut out and none of the pieces fell out. Precision laser cut from 1.5mm brush stainless steel – our laser cutting machine provided clean, burr free edges and once bent, the part was ready to be fitted to the bike.

The diversity, flexibility and precision of laser cutting makes it ideal for a whole host of applications – we can combine this process with many of our other in house processes such as printing, etching and laser marking. The combination of two processes allows for a part to be durably marked or printed with an impeccable finish and cut with precision accuracy. Utilised across a range of industries including hospitality, aerospace and defence, automotive, electronics, manufacturing and all the weird and wonderful projects in between!

Our experienced team of laser technicians have many years applying these process to a large variety of materials such as aluminium, stainless steel, copper, brass, wood, laser laminates and acrylic. We pride ourselves on producing quality products by using market leading technology and are true experts in our field.

With a wealth of knowledge gained through years of extensive research and experience our dedicated team are on hand to guide you through the best process for your requirement.

Contact us to discuss your project.

“Thank you again for a super job! I think it finishes my bike off a treat.

Let's discuss your project.

Whether you have a full brief or just an idea, we'd love to share our expertise with you.

Contact us“Please accept this as a very late thank you to Fine Cut, and especially Colin & Keith for stamping and labelling our spectacle frames. Thanks”

“What a service!! I have just received back my hand tool with a lovely new handle, by return and at no cost to myself – I can’t thank you enough for your...”

“The overlays have just arrived – and they’re outstanding, you’ve got a VERY happy customer : ) Please send my personal thanks to the team for getting...”

“We have received the memorial plaques this morning and I just wanted to say how delighted we are with them. The quality and craftsmanship are superb and I...”