Screen printed Aluminium Cases

Case Studies

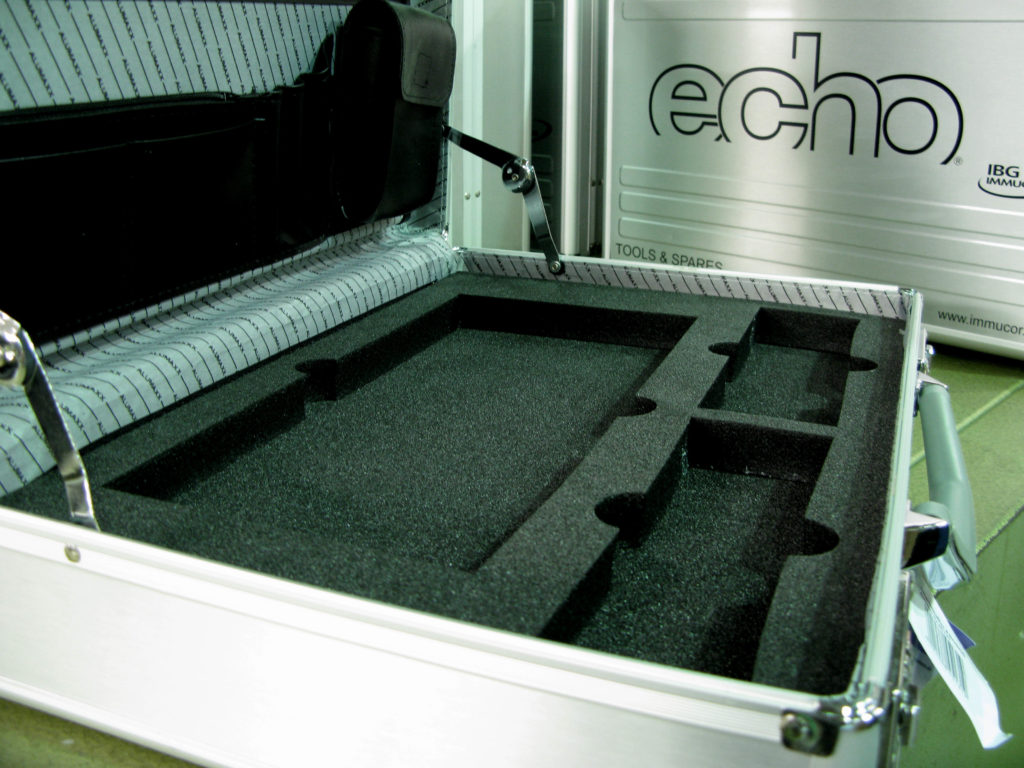

Screen printed aluminium cases with company branding and laser cut foam inserts – all supplied and manufactured by Fine Cut.

The cases were designed (in two different variants) for the customers engineers to keep their important tools & spare equipment organised. Fine Cut advised the customer throughout the entire design process, producing several design variations from the logos supplied. The difficult task of incorporating the design around the bevelled pattern of the case fascia was successfully achieved.

Eventually, the same design was chosen for both variants and the entire batch were screen printed with a solvent air drying black ink, which gives a very durable finish – ideal for rugged use and can withstand transportation wear and tear.

To complete the project, Fine Cut also needed to replicate the foam inserts from an older version of the case – which were designed to securely hold important components within the case. Again our in-house design team produced a computer generated pattern which were then laser cut from 20mm foam. Using the our laser cutting machinery proved to be a quick and efficient way to get an exact replica of the patterns in multi batch lots.

Fine Cut saw the project through from start to finish – designing & printing the external branding, producing accurate patterns and laser cutting internal cavities – and all under one roof.

Our customer provided these kind words:

“Everyone here is very impressed with the tool cases, so thank you very much for doing a splendid job with them!”

Let's discuss your project.

Whether you have a full brief or just an idea, we'd love to share our expertise with you.

Contact us“I just wanted to say a massive thank-you to all of you, the parts came in this morning. They look really nice and you turned them round really quick for us!...”

“I just wanted to thank you on your service because it was truly outstanding, to the point that one of your guys actually help me jigsaw the letters into the...”

“I was very happy with the recently delivered labels and will will be ordering again soon. Also I will use Fine Cut from now on for any other projects.”

“Just a belated note to say thanks for your help, the labels look great, easy to fix and the College absolutely love them!”