Hotfoil Marking

Processes

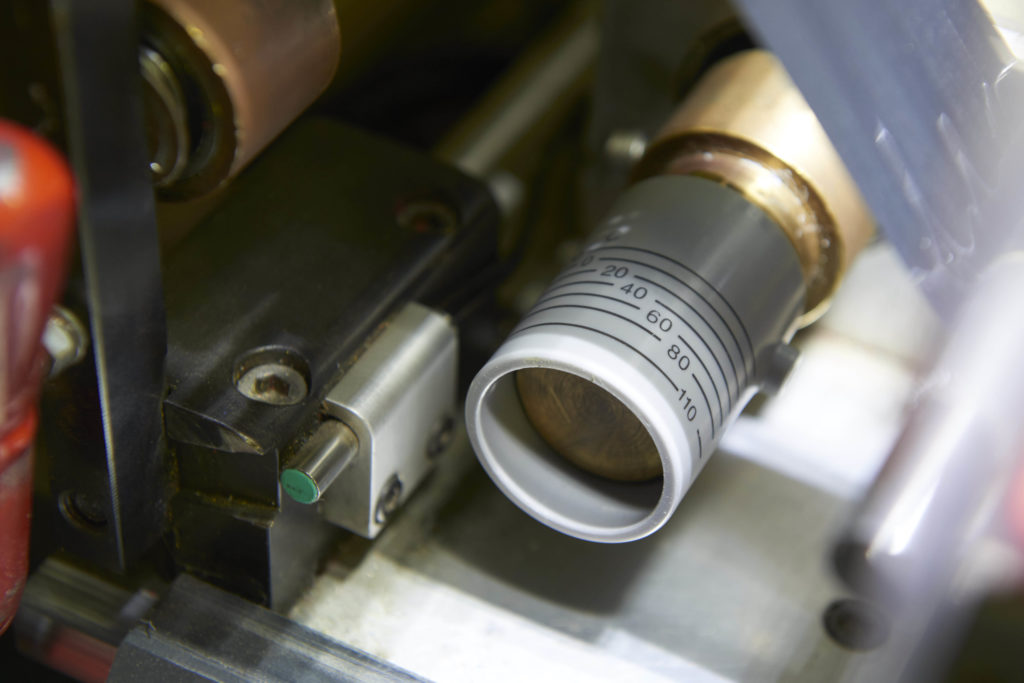

Although not technically a printing method – hotfoil uses a heated die to adhere foil with pressure to a variety of substrates. Finishes can be either surface foiled or embossed and foiled on to softer substrates for a more luxurious finish.

Technical Spec

Process Features

- Flat | convex | concave | cylindrical shapes

- Spectrum of colours including metallics

- Rotary printing up to 90mm diameter

- Completely bespoke designs

- Achievable on a variety of materials & free issue parts

Typical Applications

- Badges

- Automotive

- Components

- Thumbwheels

- Leather goods

- Stationery goods

- Free issue parts (<15mm depth / 90mm dia)

Material Options

Name:

Plastic

Finish:

Any

Thickness:

up to 15mm

Name:

Paper

Finish:

Any

Thickness:

up to 300gsm

Name:

Card

Finish:

Any

Thickness:

up to 540gsm

Name:

Leather

Finish:

Natural | Suede | PU

Thickness:

up to 3mm | up to 15mm if book cover

Name:

Fabric

Finish:

Natural | Synthetic

Thickness:

up to 1mm | up to 15mm if book cover

Name:

Wood

Finish:

Man made | Natural | Synthetic

Thickness:

up to 15mm

Name:

Free Issue Parts

Finish:

Any within parameters

Thickness:

up to 15mm / 90mm dia

Maximum Size

Maximum print area - 150mm x 100mm

Maximum diameter 90mm

Maximum diameter 90mm

Durability

- Inside

Abrasion:

Light abrasion - although hot foil is a durable method

Liquids:

Light cleaning and spill proof - do not submerge

Chemicals:

Not recommended

View Our Work

Latest Insights

Browse our curated section of news and useful articles.

Let's discuss your project.

Whether you have a full brief or just an idea, we'd love to share our expertise with you.

Contact us“Just wanted to say a great big thank you to you and your team for getting the labels to us so quickly, your continued help is very much appreciated.”

“Thanks to your technicians for the excellent job they have done laser cutting and marking the Hounds.. Attention to detail is wonderful.. Thank you all so much...”

“Thank you for helping us to get the flasks engraved so quickly. They look great!”

“Please accept this as a very late thank you to Fine Cut, and especially Colin & Keith for stamping and labelling our spectacle frames. Thanks”