Could new adhesive be the key to the final frontier?

News

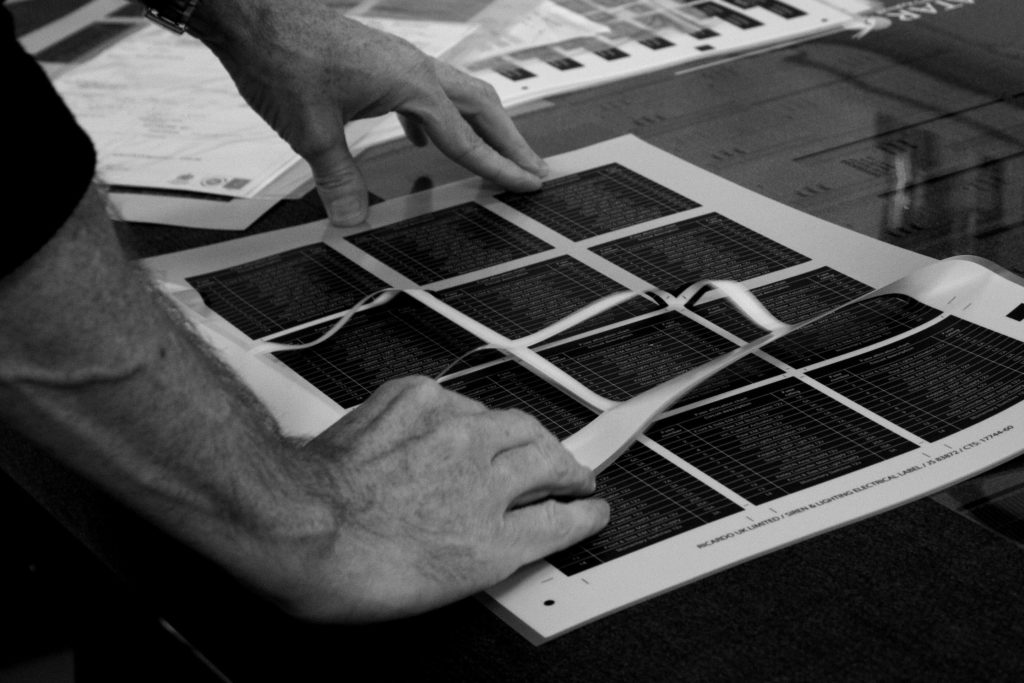

A key consideration for every label we produce is its application – because if it is unable to stick to the surface it is intended for, then this can be a pretty fatal problem!

From deep-sea environments to the desert, finding the right adhesive to do the job can sometimes provide our staff with a challenge, so it’s important to keep up to date with the latest news within the adhesive industry.

One such example is a product that was developed by the European Space Industry (ESA), which could be used to bond materials that will spend a large amount of time orbiting the Earth – or even further afield in the great beyond.

Space represents perhaps the most challenging environment for creating an adhesive. The lack of an atmosphere means the temperature of a satellite, for example, can vary by hundreds of degrees celsius depending on which side is facing the sun.

In addition to this, objects never stay still, so the pressure that the adhesive and the materials it is bonding will come under can be significant.

To solve this problem, a silicone-based adhesive was developed in Italy following a period of testing against heat, moisture and force.

ESA materials engineer Laurent Pambaguian said: “A new adhesive was baselined, with the possibility of adding ceramic fillers to optimise its compatibility with bonded materials while keeping its moisture insensitivity – tailoring its characteristics to our requirements.”

“At the end of this work, we can say the dream of ultra-stable materials is in sight,” he added.

The adhesive was initially to be used to bond panels of carbon-carbon, a composite described as being “lighter than aluminium while stronger than steel”. It is hoped it will eventually be utilised to manufacture space structures such as telescopes.

Our experts can recommend the best adhesives for your requirements – get in touch to discuss your options.

Let's discuss your project.

Whether you have a full brief or just an idea, we'd love to share our expertise with you.

Contact us“Thank you and your team for the speed with which you created and supplied the Turkish label sets. Your efforts are greatly appreciated.”

“Thank you to all the team at Fine Cut. At every stage of the process you were on hand with help and advise and as a result, it was a really enjoyable journey...”

“Very happy. Thank you so much. I’ll be in touch with further work! Excellent staff.”

“Just to thank you for the lettering and stencil. I applied the letters this afternoon, it was easy and they look great.”